- Current limiter signal enables feedback control

TOKYO — (BUSINESS WIRE) — September 25, 2018 — Toshiba Electronic Devices & Storage Corporation (“Toshiba”) today launches an integrated dual H-bridge DC brushed motor driver IC that includes an output current limiter function rated at 50V / 3.0A. The new TB67H401FTG device can handle applications where monitoring and feedback of the motor state is necessary, including office equipment, ATMs, home appliances, robotic cleaners and more—all devices that have grown in popularity in recent years and that often incorporate DC brushed motors.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20180925006329/en/

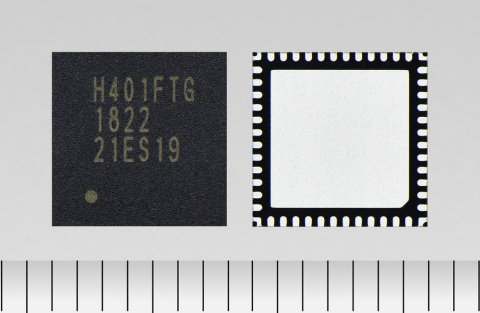

Toshiba: An integrated dual H-bridge DC brushed motor driver IC "TB67H401FTG" that includes an output current limiter function. (Photo: Business Wire)

Until now, safe control of DC brushed motors has been accomplished by limiting the upper value of the motor current through a constant current limit. Over current is generated by the motor lock and is read from an external resistor through external circuitry, operational amplifiers and comparators, which increases the component count and circuit complexity.

The highly integrated TB67H401FTG is fabricated with Toshiba’s BiCD process and has an inbuilt flag output circuit, which monitors the current state and indicates when it has reached the upper threshold. This ends the need for external circuitry and delivers smaller, more efficient motor solutions with reduced BOM costs.

The TB67H401FTG supports a total of four drive modes; forward (CW), reverse (CCW), brake (short brake) and stop (off). It also includes a mode switching function that extends the application range. Single-bridge mode supports a single channel current of up to 6.0A, while dual-bridge mode allows use of two motors, with a single IC driving up to 3.0A per motor.

The low on-resistance MOSFETs incorporated into the H-bridge (High side + Low side =0.49Ω typ.) ensure low losses and efficient operation. An internal regulator allows the device to be driven from a single 5V supply.

The tiny device is housed in a 7mm x 7mm x 0.9mm QFN48 package, which also includes thermal shutdown detection, over current protection and under voltage lockout. A general error detection signal enhances system safety by providing a warning to the main system controller.

TB67H401FTG is now in mass production.

Applications

Applications that need to

monitor and feedback results on the motor drive state—industrial

equipment, including office equipment and ATMs, home appliances, and

robotic cleaners.

Main features

1. Flag output function

A

flag output function outputs results from the current limiter detection

to an external device. It helps reduce the number of external amplifiers

and comparators.

2. Mode switching function (single-bridge and dual-bridge modes)

Single-bridge

mode supports high load drives (large current drive of 6.0 A).

Dual-bridge mode supports driving of two motors with a single IC (3.0 A

/ 2 channels). It widens the range of applications.

3. Other error detections

Thermal shutdown detection, over current

protection, and under voltage lockout. The error detection signal can be

output to the external device, helping to enhance safety.

|

Main specifications |

||

| Part number | TB67H401FTG | |

| Control I/F | Parallel inputs | |

|

Absolute

|

50 V, 6.0 A (Single bridge mode),

50 V, 3.0 A (Dual bridge mode) |

|

| Package | QFN48 (Size: 7 mm×7 mm×0.9 mm, pitch of pins: 0.5 mm) | |

| Drive Mode | Forward (CW), Reverse (CCW), Brake (Short brake), Stop (OFF) | |

| Other features |

Built-in flag output function that shows the result of the current

limiter detection.

Switch between single-bridge mode and dual-bridge mode Built-in current limiter function (constant current PWM control) Error detection signal output function (Thermal shutdown, over current protection, and under voltage lockout) Supports the power-on sequence by the single power drive. |

|

|

Stock Check &

|

||