TOKYO — (BUSINESS WIRE) — March 30, 2015 — Toshiba Corporation (TOKYO: 6502) today announced the launch of “TB9057FG”, a brushed motor[1] pre-driver IC enhanced to achieve functional safety and for use in electric power steering systems (EPS). Sample shipments will start on April 1st, 2015, with mass production scheduled to start in November, 2016.

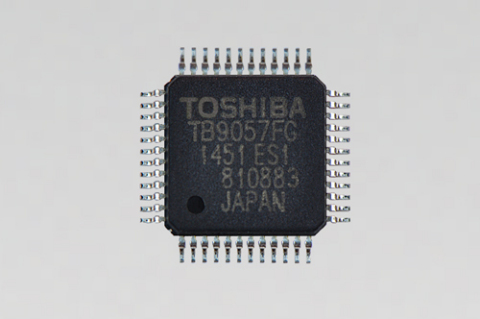

Toshiba: a new brushed motor pre-driver IC "TB9057FG" for automotive EPS (Photo: Business Wire)

More and more safety-critical automotive systems, such as EPS are required to meet the requirements of ASIL-D [2], the highest automotive safety integrity level prescribed in ISO 26262, “Road Vehicles – Functional Safety.”

The new IC integrates key main functions, such as a pre-driver[3] circuit, motor current detection circuit[4], and motor direction detection circuit[5], plus various failure detection circuits, while functions including motor current detection circuit, power supply PIN, and GND PIN are made redundant to secure higher functional safety.

Toshiba has also carried out a range of functional safety analyses to simulate various system failures and will provide customers with documentation to support safety analysis and design.

Key Features

1. Various failure detection circuits for

functional safety

Built-in VB under voltage detection

circuit, VDD under voltage detection circuit, over temperature detection

circuit, and short detection circuit[6].

2. Redundant function supporting functional safety

Dual

motor current detection circuit for safety-critical systems, such as

EPS. Power supply PINs and GND PINs have redundant configurations.

3. Under voltage operation

In

consideration of voltage drop caused by cranking after idling reduction,

the battery operation voltage range is improved down to 5V (min.) from

6V (min.) of the previous product.

4. Built-in motor current detection circuit and

motor direction detection circuit

Simplifies systems and

reduces PCB size.

5. Pre-Driver operation is selectable on failures

detection.

Customers can set the system to respond to

detected failures in one of two ways, using the input setting of the SEL

pin. One setting uses this new IC to stop the external MOSFET, the other

switches to external control of the MOSFET using the MCU. Selection can

be made according to the customer’s application or system, and reduces

loads on the MCU.

|

Main Specifications |

||

| Part Number | TB9057FG | |

| Mass Production | November, 2016 | |

| Sample Price(tax included) | 300 yen | |

| Mass Production Volume | 1 million units per year | |

| Channels | 4 channels (high side: 2 channels, low side: 2 channels) | |

|

Operating

Voltage Range |

+5 to 21V | |

| Operating Temperature Range | -40 to 125°C | |

| Input signal | Made for a direct control | |

| Detection Circuits | VB under voltage detection circuit, VDD under voltage detection circuit, over temperature detection circuit, short detection circuit | |

| Motor Current Detection Circuits | Converts motor current to voltage and output to MCU | |

| Motor Direction Detection Circuits | Detects whether external MOSFET turns on or off normally and output the direction information to MCU. | |

| Package | LQFP48-P-0707-0.50C(9.0mm × 9.0mm × 1.6mm) | |