MAPLE PLAIN, Minn. — (BUSINESS WIRE) — February 7, 2017 — Proto Labs Inc. (NYSE: PRLB), a leading online and technology-enabled quick-turn manufacturer, officially launched its insert molding service at Pacific Design & Manufacturing in Anaheim this week, expanding on the company’s rapid injection molding offerings. This new capability can produce 25 to 10,000-plus insert-molded parts in 15 days or less.

This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20170207005003/en/

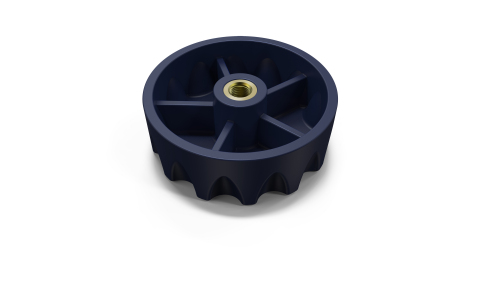

Quick-turn digital manufacturer, Proto Labs, has added insert molding services to their offerings. The company uses advanced 3D printing, CNC machining and injection molding technologies to produce custom parts within days. (Photo: Business Wire)

“We’re delighted to now be delivering a new service that designers and developers have been asking us for,” said Proto Labs CEO Vicki Holt. “As we help companies large and small accelerate their product development with our digital manufacturing methods, insert molding offers another important tool for these companies to make prototype or end-use parts as quickly as possible.”

Insert molding is the process of overmolding thermoplastic material around a preformed component (an insert) to create a finished part that incorporates multiple materials. The inserts are generally metal parts that are used to reinforce the mechanical properties of the plastic part. The metal inserts are placed into the mold to form the part.

A variety of components are manufactured with insert molding, such as electronic parts, medical equipment, housings, knobs, handles and dials, and are found in several industries, such as medical, automotive and consumer products. Product designers and engineers frequently turn to insert molding for improving part strength while trimming part weight and reducing assembly costs, production time and labor.

“With quick-turn insert molding services at Proto Labs, I was able to receive functional prototypes in weeks,” said Chris Mazzucco, Design and Development Engineer at Zebra Technologies, an Illinois-based information technology company that manufactures and sells marking, tracking and computer printing technologies.

Proto Labs will be at the Pacific Design & Manufacturing Show in Anaheim Feb. 7-9. Visit booth #3415 to learn more about the company’s insert molding services and other rapid manufacturing processes.

About Proto Labs

Proto Labs is the world’s fastest digital

manufacturing source for custom prototypes and low-volume production

parts. The technology-enabled company uses advanced 3D printing, CNC

machining and injection molding technologies to produce parts within

days. The result is an unprecedented speed-to-market value for designers

and engineers and an on-demand resource throughout a product’s life

cycle. Visit protolabs.com for more information.

View source version on businesswire.com: http://www.businesswire.com/news/home/20170207005003/en/

Contact:

Proto Labs Inc.

Sarah Ekenberg, 763-479-7560

Email Contact

or

Media

Contact:

PadillaCRT for Proto Labs

Tim Nelson,

612-455-1789

Email Contact