Leading Reverse Engineering Software Now Seamlessly Integrated with Autodesk Inventor 2024

LA JOLLA, Calif. — (BUSINESS WIRE) — December 27, 2023 — HighRES Inc, operating under the name ReverseEngineering.com™, a distinguished Autodesk certified partner, proudly announces the certification of its cutting-edge reverse engineering software, the "RE" app 2024, under the Autodesk Certified Apps Program. This prestigious certification reflects the software's exceptional quality and seamless integration capabilities with Autodesk Inventor 2024.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20231227754641/en/

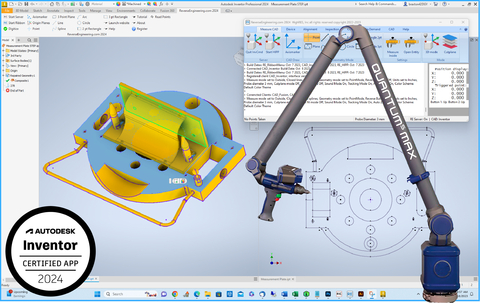

ReverseEngineering.com 2024 - Autodesk Inventor 2024 Certified app connects Faro arm and Romer Absolute arm direct to Inventor. 3D Measurement software for shop floor enables 3D capture of fixtures, tooling, molds, models or MRO parts. (Graphic: Business Wire)

The RE app 2024 is specifically engineered to establish seamless connections with Faro Arms and Romer Absolute Arms. This transformative integration enhances collaboration between Portable Coordinate Measuring Machines (PCMMs) and Inventor, empowering users to capture intricate details such as tooling, worn parts, and obsolete components with precision.

As noted by Braxton Carter, President of HighRES, Inc., "The combination of portable CMMs, calipers, and micrometers provides a comprehensive and flexible metrology solution. Manufacturers and engineers can achieve accurate and efficient measurements across a wide range of components and applications by leveraging the unique strengths of each tool."

This synergy between the RE app and these measurement tools not only streamlines the measurement process but also ensures that a diverse array of components can be accurately assessed, contributing to increased efficiency and productivity across various industrial applications.

The integration of 3D measuring arms with Inventor establishes a robust tool for 3D measurement, digitization of wireframes, and the capture of sketch planes and circles for fixtures, tools, molds, and worn parts. This innovation empowers shop floor managers to minimize waste, enhance efficiency, and boost floor productivity, ultimately leading to increased profitability.

The RE app's intuitive workflow supports the 3D/2D capture of physical parts surfaces, allowing users to effortlessly capture points, lines, splines, planes, circles, rectangles, and more by placing the tactile probe tip on the part surface.

Key Features and Benefits:

- Live DRO XYZ Digital Readout: Quickly determine the location with a live DRO XYZ digital readout and a tracking 3D cursor on the Inventor screen.

- Dual Triggers: Utilize two triggers on the 3D measurement arm—one for data collection and another for concluding the process.

- Direct Integration: Activate the Faro arm or Romer arm into a precision mechanical CAD data capturing tool with a simple mouse click.

- Universal Functionality: Eliminate the need for multiple stand-alone reverse engineering software solutions; perform 3D digitization, reverse engineering, and 3D/2D measurement directly in Autodesk Inventor.

- 3D scan and process point clouds for Mesh surfaces and profile extraction.

Braxton Carter, President of HighRES, Inc , remarked, "With the ReverseEngineering.com add-in, you will no longer need multiple stand-alone reverse engineering software solutions. Simply 3D digitize, reverse engineer, 3D/2D measure, or inspect directly in Autodesk Inventor."

About ReverseEngineering.com: Headquartered in La Jolla, California, ReverseEngineering.com is a leading company dedicated to direct CAD reverse engineering and measurement software solutions worldwide. Since its founding in 1995, the company has developed and marketed 3D scanning software toolsets that seamlessly manage digitized data from portable and traditional CMMs, laser trackers, and laser scanners into CAD/CAM/CAE systems as easily modifiable parametric sketches. ReverseEngineering.com is an Autodesk Inventor certified partner, Solidworks Certified Gold partner, and collaborates with Ansys Discovery SpaceClaim, PTC, MasterCam, Kubotek, OnShape, and Siemens Solidedge/NX. Customers include PENSKE Technology Group, GE Healthcare, U.S. Army Special Forces, Los Alamos Labs, U.S Air Force, and the U.S. Navy.

For more information on ReverseEngineering.com and their products, please visit www.ReverseEngineering.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20231227754641/en/

Contact:

Media Contact

Cynthia Fleek

ReverseEngineering.com

858-488-5231

mediarelations@reverseengineering.com